This modification was carried out on a JVC JL-F30

turntable. It is a standard 'belt drive' table with a brass motor spindle.

The following operations should work with most any 'belt drive' table that

has a motor spindle that resembles the one shown in these photos.

|

Removing the platter should expose a mechanism similar to

this. This is a typical '2-Step', 33 1/3 / 45 RPM turntable spindle /

pulley. It's made of brass and is held on to the motor shaft with a set

screw. Of course you could do the calculations and have a machine shop

increase the circumference, but one of the words in the title of this page

was 'CHEAP'...

|

Using simple vinyl electrical tape, we are going to wrap

it around the motor spindle, which increases it's circumference, thus

increasing the belt travel speed.

|

Using a razor blade and a steady hand, split the tape

into a width appropriate for the 45 RPM (larger) section on the motor

spindle.

|

|

|

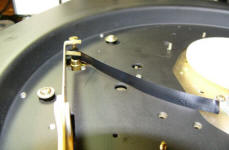

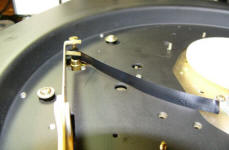

Since the motor spins 'clockwise', the wrap should start

on the left or 'leading edge' of the pulley.

|

Finished wrap for a simple 'speed correction'.

|

This was a short section of tape we used for 'speed

correction', not 45 to 78 RPM conversion.

|

|

|

This was a longer section we cut to do the 45RPM to 78RPM

conversion, just after starting the wrapping process.

|

We found it handy to put an index mark with a Sharpie

marker to keep track of the number of wraps / turns. It was best to put the

speed fork in the '45' position to make grasping the top of the pulley

easier.

|

Then start wrapping...

|

Once wrapped it should look like this.

|

|

You could also use 'shrink wrap / tube' either the sheath

the tape, or simply use successive layers of shrink tube in lieu of tape.

|

Here is the built-up pulley with the belt installed.

|

JVC belt drive turntable successfully playing a 78 RPM

record.

|

Our speed testing was

verified with strobe disc that showed +4%, +2%, 0, -2% and -4% results.

|

You would think by doing this that you would introduce a bit of 'flutter' to

the sound of a turntable, and I'm sure on a minute level you do, but in

testing with a 'test tone' record, there was essentially none detected. We

have not tested the integrity of the tape 'long term', only for about 12

hours. Upon inspection after that time, the tape and it's leading edge

showed no significant signs of wear. We found that 1 layer of tape = about

3% at the 45 RPM dimensions. 13 wraps on the 45 RPM portion of the pulley /

belt spindle (about 6.5" of tape) resulted in 78

RPM at +2%, starting with a table that was already running at -4% prior to

starting the mod (sorry, but we didn't spend the time to 'add tape' to get

the table 100% 'dead-on', then add tape to get the 78 speed 'dead-on', but

you get the drift.

You would still need to address the correct stylus / needle or entire

cartridge replacement for playing 78 RPM records, as most cartridge / stylus

/ needle combinations designed for 33's are going to make 78's sound even

thinner / tinney'er.

NO OTHER INFORMATION, NOR ASSISTANCE AVAILABLE

|

-

ATTENTION: We recommend you DO NOT DISASSEMBLE or ATTEMPT TO REPAIR OR

REPLACE ANY PARTS ON ANY ELECTRONIC / ELECTRICAL DEVICE without proper,

technical training and repairs / modifications should always be left to

qualified technicians.

|

The information contained here is

simply my personal findings and is not intended for anyone / or any entity to

use to make any decisions to repair, disassemble, modify, or do anything. It is

strictly for entertainment value. Please do not email any responses or call with

any information related to it. It is also likely to change as new / additional

information comes to light, or I change my mind or opinion. So There!