Our Testing and restoration methods:

Receivers / Tuner /

Pre-amps

Power-amps,

Guitar Amps:.JPG)

.JPG)

Initial check-in and test for basic function:

First check to see that the unit is set for correct North American

Voltage. Then we pull the cover / housing and do a visual check for

burned components, bad fuses, swollen / leaking capacitors, excessive

grime, critters (yes we've found a few mouse nests) and dust or any

other obviously problems. We then check for a 'hot

chassis', meaning does it have voltage between the chassis, face, knobs

etc to ground. We do this because we once had a unit that an 'amateur'

had worked on at some time in the past, prior to arriving to us. This

person had erroneously connected a wire to a 'hot lug' of the power

switch to the chassis, instead of the correct location. Somehow when the

unit was powered off, it had 120VAC going to the chassis. Our tech had

his hand on the chassis, and reached up to adjust his articulating arm,

bench light. He had a full 120 Volts pass from one hand, completely thru

him to his other hand. Fortunately, somehow, other than sore arms for a

couple of days, he survived unscathed, but technically that was a

'lethal' situation and could have had, and probably should have had much

more serious results. We 'dodged a bullet'.

If nothing raises alarm we power up slowly on

a Vari-AC to check for any early excessive current draw. At full current

after about 10 minutes, we then check for excessive DC 'offset' at the

outputs before we connect any test speakers. We then check for AC noise at the

outputs. Assuming the unit passes to this point we then evaluate

condition of controls, panel lamps, output sine wave quality (using an

oscilloscope, an AF gen, appropriate dummy load and volt meter) noting

overall quality of the sine waves. Then and only then, do we feel

confident to connect to a speaker load for initial 'listening tests'. A

piece of gear that has an unusually heavy build up of dust, grease and

grime on the output devices and the rest of the circuitry will probably

get salvaged even if it does work, as an excessive amount of grime means

that the components have been allowed to run hot, thus shortening their

life span. Heat is the number one killer of electronics and parts that

have an excessive amount of dirt and grime build-up cannot dissipate

heat adequately. In addition if you can see that much dirt

on the surface, inevitably it has gotten in places where it can’t be

cleaned and may cause future problems. Units that have been used in

bars, kitchens, garages and shops or in environments with heavy smokers

and or lots of dust are to be suspect.

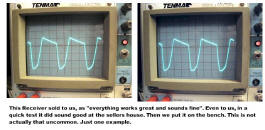

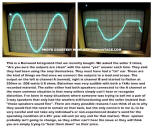

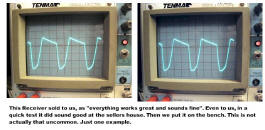

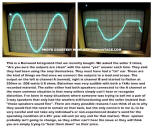

Here is a recent example of two identical models that came in on

trade from the same person. He had 'taken the gamble' and purchased one,

from a fleeeebay seller who of course said that the unit 'tested fine',

'work as intended', 'sound great', blah, blah blah... He had read about

the 'stellar' performance units we had previously had of the same model,

and once it arrived, felt that it fell far short sonically, but couldn't

'put a finger' on why. He then tried a second unit from another seller,

stating similar condition, with the same results. We don't normally do

outside repairs, but since I knew him, and he was local, we agreed to

take a look at them, and if nothing else, work a potential trade-in

towards one of our 'refurbished' units. After establishing a basic

'state of health', we found that while both were running 'hot', one was

running 'scalding' hot (220 plus degrees! at the heat sink). They

both did work, and the tuners and all basic functions were there, and

they each didn't sound necessarily offensive, but upon further testing

into a dummy load and on a scope, we found bias issues. When a basic

bias adjustment was initially attempted, neither unit would respond, no

matter how far the adjustment pot was 'racked' in either direction with

one idling at 63ma!!!.

<--photos of Sansui units

<--photos of Sansui units

Both units required EXTENSIVE driver board rebuilds (2-3 hours each of

tech time for new capacitors and driver transistors). There were other

typical issues that were also addressed, but once done we were able to

decrease the temperature down to about 'room temperature' on both. At

220+ degrees at idle, they wouldn't have lasted long, to say the least.

Just FYI when you're considering the unit from an 'amateur' electronics

seller that says 'its all good'.

Once we do an initial check-in we vacuum, use compressed air, and

brushes to remove all the dust, dirt and grime from the inside of the

unit. We strip the unit to the level of cleaning it’s controls and

switches, which sometimes even means individually removing the controls

from the circuit board completely to do a thorough cleaning.

It can sometimes take up to 2 hours just to gain access to clean a units

controls.

We also check for obvious past repairs that may not have been done

“professionally”. We next check and / or replace any burned or

intermittent panel / pilot / meter / indicator lamps. Next any internal

memory back-up batteries / capacitors are checked or replaced. We

inspect for any “cold” or loose solder joints especially on the input /

output jacks and ground / ground-chassis, pots and switches or any other

parts that might have force or flexion applied to them. RCA jacks are

notorious for developing loose solder joints especially on gear newer

than 15 years or so due to manufactures choosing to solder jacks

en-mass directly to the circuit boards to save money. Cheaper as it may

be, it’s a terrible design that will inevitably fail after just a few

uses. The same goes for abandoning the use of quality control pots that

use a nut to secure it to the chassis / face-plate. Many units

manufacturers switched to using control potentiometers that are soldered

to the circuit boards and simply stuck through a hole in the face

with no “shaft nut” to secure it. Every time you manipulate the control

you stress the solder joint. Some fare well,

but most do not over just a few

years of use. Two terrible designs that are common on the vast majority

of gear manufactured after the early 1980’s but I just had to get on the

“Soap Box” about them. We also proactively

re-flow most solder joints associated with 'heat' producing components

such as 'voltage regulators' and 'power resistors' as even though they

may not 'yet' be completely bad, they are almost always in some 'state

of going bad soon'. We also check for transistors / diodes /

semiconductors with 'black or green legs'.

We also check for obvious past repairs that may not have been done

“professionally”. We next check and / or replace any burned or

intermittent panel / pilot / meter / indicator lamps. Next any internal

memory back-up batteries / capacitors are checked or replaced. We

inspect for any “cold” or loose solder joints especially on the input /

output jacks and ground / ground-chassis, pots and switches or any other

parts that might have force or flexion applied to them. RCA jacks are

notorious for developing loose solder joints especially on gear newer

than 15 years or so due to manufactures choosing to solder jacks

en-mass directly to the circuit boards to save money. Cheaper as it may

be, it’s a terrible design that will inevitably fail after just a few

uses. The same goes for abandoning the use of quality control pots that

use a nut to secure it to the chassis / face-plate. Many units

manufacturers switched to using control potentiometers that are soldered

to the circuit boards and simply stuck through a hole in the face

with no “shaft nut” to secure it. Every time you manipulate the control

you stress the solder joint. Some fare well,

but most do not over just a few

years of use. Two terrible designs that are common on the vast majority

of gear manufactured after the early 1980’s but I just had to get on the

“Soap Box” about them. We also proactively

re-flow most solder joints associated with 'heat' producing components

such as 'voltage regulators' and 'power resistors' as even though they

may not 'yet' be completely bad, they are almost always in some 'state

of going bad soon'. We also check for transistors / diodes /

semiconductors with 'black or green legs'.

This is an issue that we are

seeing more and more often as time marches on, especially to some

transistors. This is oxidation that is happening to the metal leads,

that then migrates up into the epoxy body of the device. If it migrates

far enough in (and it sometimes does), it can / will compromise the

internal contact with the devices substrate thus compromising

conductance. Often this can be deduced by physically manipulating a part

that is being intermittent, or by heating / cooling them. Sometimes they

are past that and just don't ever work and simply need to be replaced

along with any others exhibiting 'black or green' oxidation.

This is an issue that we are

seeing more and more often as time marches on, especially to some

transistors. This is oxidation that is happening to the metal leads,

that then migrates up into the epoxy body of the device. If it migrates

far enough in (and it sometimes does), it can / will compromise the

internal contact with the devices substrate thus compromising

conductance. Often this can be deduced by physically manipulating a part

that is being intermittent, or by heating / cooling them. Sometimes they

are past that and just don't ever work and simply need to be replaced

along with any others exhibiting 'black or green' oxidation.

We check for a particular 'glue / epoxy' that was often

used in the 70's and 80's to secure heavier devices such as larger

electrolytic capacitors & voltage regulator heatsinks. In some instances

it has become conductive and must be removed / replaced so as not to

compromise the performance of the circuit.

We check electrolytic capacitors for any signs of

leakage (physical / chemical, not electronic), bulging, splitting etc.

We also often check them electronically for proper capacitance, ESR and

we can test leakage up to 600Volts! If deemed necessary, we also can do

a leakage test that actually looks at the rate of leakage / bleed off.

As time marches on, we are having to be aware of the

above points more and more often, which unfortunately, increases end

unit prices due to additional tech time / parts resources. Fortunately

however, that means that most of those part addressed with not likely be

an issue for another 2-3 dozen years.

We check tuner dial cords / mechanisms for

freedom of motion, frayed tuner string, binding string at flywheel,

string slip and alignment, replacing where necessary. We also check

tuners on all bands for quality and re-align the tuner "front-end" as

most have drifted in performance due to semiconductor age, wear and

dirt. Next face plates / housings / patch-bays and knobs

are painstakingly cleaned and polished. Entire unit is detailed to look

as close to new as practical. Bent control shafts are straightened.

Questionable or stiff AC cords are replaced. Wood cabinets are oiled.

Loose trim is repaired. The unit is then re-tested for all functions and

output quality. Our test for output quality and control

potentiometer cleanliness is not simple listening through a set of

speakers. We 'look' at the sine waves to make sure the controls are

clean. We test one side / amplifier at a time currently. These tests are

not to test for "original spec" or deviation from that, but to test the

overall health of the pre-amp / power-amp section. We connect the

outputs individually to a “Static /

brick-wall load” that can vary from 0-32 ohms.

Most amplifiers are tested at both 4 & 8 ohms. We first do an 8-ohm

test. In addition to the “dummy (static) load” we connect a calibrated digital

volt meter and an oscilloscope to the outputs. To the inputs we connect

a sine-wave generator producing a 1 kHz tone with .775 volts output*. We

bring the amplifier slowly up to “clip” or to it’s power rails

noting that it hits both rails simultaneously. If it is hitting one rail

in advance of the other it indicates a bias problem which means that the

output devices are either over biased or under biased and will need to

be adjusted if practical, or if there's a defective part, it is replaced

if practical.

Loose trim is repaired. The unit is then re-tested for all functions and

output quality. Our test for output quality and control

potentiometer cleanliness is not simple listening through a set of

speakers. We 'look' at the sine waves to make sure the controls are

clean. We test one side / amplifier at a time currently. These tests are

not to test for "original spec" or deviation from that, but to test the

overall health of the pre-amp / power-amp section. We connect the

outputs individually to a “Static /

brick-wall load” that can vary from 0-32 ohms.

Most amplifiers are tested at both 4 & 8 ohms. We first do an 8-ohm

test. In addition to the “dummy (static) load” we connect a calibrated digital

volt meter and an oscilloscope to the outputs. To the inputs we connect

a sine-wave generator producing a 1 kHz tone with .775 volts output*. We

bring the amplifier slowly up to “clip” or to it’s power rails

noting that it hits both rails simultaneously. If it is hitting one rail

in advance of the other it indicates a bias problem which means that the

output devices are either over biased or under biased and will need to

be adjusted if practical, or if there's a defective part, it is replaced

if practical.

Either problem can and usually does result in outputs either running too

hot (which shortens their life drastically) or running too cold which

will usually result in a “mushy” sound with no "punch". If the signal

looks good we note the voltage output and do the math to figure "peak"

wattage (you can use the voltage / load figures to deduce RMS output if

you wish). We then lower the load impedance to 4 ohms and repeat the

tests and then on to 2 ohms if the amplifier is designed to run that

low. We also manipulate the controls with the sine-wave to check for

dirt induced static as smaller amounts will show up readily on the

scope, but may not be heard readily with your ears. If there’s a problem

we re-clean or replace the controls and re-test. We then re-assemble the

unit completely and it goes to another test bench. Here it is hooked to

a signal (usually utilizing the tuner with a quality antenna) and to a

pair of speakers. All the tone controls are maxed and the

Loudness control (if available) is engaged. It is then “burned-in” for a

period of not less than 12 hours at a moderate volume ( and sometimes up

to 72 hours) to check for any intermittent / heat related problems. Once

it passes all of the above tests it is tagged and bagged to await

shipment. (*We choose the “1 kHz into one channel at a time” testing

method as we believe it provides greater accuracy as to the health of

each channels output section. The alternative and other extreme would be

to load both channels simultaneously with full bandwidth pink noise or

1k and then do the measurements. It is difficult, if not almost

impossible to tell when pink noise is truly clipping and you can’t check

potentiometer condition using this technique. While the latter technique

would put the power supply to a more difficult test, outputs are more

likely to have issues than power supplies. Neither test is by any

stretch of the imagination “real world”, but the 1 kHz lets us get a

good bench mark of the performance and check for control condition /

quality. The published rating of the amp will usually be about 50-80% of

what we will measure it using our method. It would be 1 to 2 times

what you would see on the bench using the pink noise method. These

methods can be subject to modification.)

Either problem can and usually does result in outputs either running too

hot (which shortens their life drastically) or running too cold which

will usually result in a “mushy” sound with no "punch". If the signal

looks good we note the voltage output and do the math to figure "peak"

wattage (you can use the voltage / load figures to deduce RMS output if

you wish). We then lower the load impedance to 4 ohms and repeat the

tests and then on to 2 ohms if the amplifier is designed to run that

low. We also manipulate the controls with the sine-wave to check for

dirt induced static as smaller amounts will show up readily on the

scope, but may not be heard readily with your ears. If there’s a problem

we re-clean or replace the controls and re-test. We then re-assemble the

unit completely and it goes to another test bench. Here it is hooked to

a signal (usually utilizing the tuner with a quality antenna) and to a

pair of speakers. All the tone controls are maxed and the

Loudness control (if available) is engaged. It is then “burned-in” for a

period of not less than 12 hours at a moderate volume ( and sometimes up

to 72 hours) to check for any intermittent / heat related problems. Once

it passes all of the above tests it is tagged and bagged to await

shipment. (*We choose the “1 kHz into one channel at a time” testing

method as we believe it provides greater accuracy as to the health of

each channels output section. The alternative and other extreme would be

to load both channels simultaneously with full bandwidth pink noise or

1k and then do the measurements. It is difficult, if not almost

impossible to tell when pink noise is truly clipping and you can’t check

potentiometer condition using this technique. While the latter technique

would put the power supply to a more difficult test, outputs are more

likely to have issues than power supplies. Neither test is by any

stretch of the imagination “real world”, but the 1 kHz lets us get a

good bench mark of the performance and check for control condition /

quality. The published rating of the amp will usually be about 50-80% of

what we will measure it using our method. It would be 1 to 2 times

what you would see on the bench using the pink noise method. These

methods can be subject to modification.)

Guitar amps get most of the same procedures listed above, but in

addition we check, record

and/or replace all the tubes (where applicable) and test / replace all

electrolytic capacitors, especially the filter caps. Reverb tanks are

checked for any internal damage, all fasteners are checked

for tightness, speakers are tested for quality / problems, cabinets are

checked for soundness and amp is test played extensively for sound

quality, tone and gain. Definitely one of the more fun parts of the job.

Tape Decks

(Cassette, 8-Track, Reel to Reel, etc):

Initial check-in and test for basic

function: First check to see that the unit is set for correct North

American Voltage. Then we pull the cover / housing and do a visual

check for burned components, bad fuses, conductive glue on circuit

board components, black or green legged diodes and transistors,

‘physically’ leaky capacitors, capacitors with shrunken wrapping,

compromised wiring, overheated / burned resistors or other circuit board

components, disintegrated / melted or otherwise out of place belts,

rodent infestations (yes, we’ve seen it multiple times),

excessive grime and dust or any

other obvious problems. We also check for obvious past repairs that

may not have been done “professionally”. Assuming the unit passes to this point,

and assuming that the rubber drive components appear to be at least

'initially servicable', we then

evaluate basic function of the deck playing first a generic tape through

the transport to make sure it doesn’t have a habit of eating tape and to

check to what degree the transport is engaging all of it’s functions

ESPECIALLY 'Fast Wind', and if equipped with 'Auto-Reverse' via a

'rotating head mechanism' that the head is rotating. We also not if the

pinch roller has divots or other issues and that it's arm assembly is

pivoting freely or to what degree it isn't. We then

check playback with test tapes noting sound quality on both channels and

accuracy of speed. We then attempt a simple record test to see if the

unit is at least imprinting a signal onto the tape and then if it will

erase it. At this point we will commonly check the

power supply board to make sure it's producing all the proper voltages

at various test points / outputs / inputs. AC floor noise

measured and noted. We next check and / or replace any burned or

intermittent panel / pilot / meter / indicator lamps (commonly we replace

them 'proactively', regardless if they currently function or not).

Once we do an initial check-in we use compressed air,

vacuum and brush to remove all the

loose dust from the inside of the unit. We strip the

unit to the level of cleaning it’s controls and switches, which

sometimes even means individually removing the controls from the

circuit board completely to do a thorough cleaning. It can sometimes

take up to 2 hours just to gain access to clean a units controls.

We'll also typically remove the transport from the

chassis (not always necessary, but often is) to service all the various

aspects of it. We

check and either re-condition or replace all rubber components.

The vast majority of the tape deck public thinks that by replacing the

belts, a tape deck can be made to run again. While belts do certainly

need to be addressed, there's also EQUALLY important, 'tires / rubber

wheels' (and I'm not talking about the pinch roller(s)) here. With only

a few exceptions, cassette decks utilize small, rubber rings / tires to

move the supply and take-up reels for both playback and Fast-Wind. Most

cassette decks will have at least one and we've seen up to 7!!! This is

critical and usually the most time consuming part of tape deck repairs.

While we stock many dozens of new, replacement tires,

it's only about 20% of the time that we have one that's correct off the

shelf. The vast majority of the time, we have to source multiple

examples before we find one that's adequate, modify one we have to an

acceptable level, fabricate one from scratch and / or recondition the

existing tires.

We’ve all seen what happens to a rubber pencil eraser after just a year

or two. It gets glazed on the surface and slick and will not erase

anything as it just slides across the paper. Or,

depending on how it was original vulcanized, rubber can revert back

to its original state, sort of a "gooey tar" substance

(most common on Pioneer products we've noticed. Nothing necessarily to

do with Pioneer as a manufacturer, but likely more to do with the

processes and methods employed by their rubber supplier / manufacturer). The same thing

happens to all the belts, tires, wheels and rollers in a tape deck or

VCR

. Fortunately it takes longer than a year, but it does typically

appear after about 8-12 years. Even if a deck is left wrapped in

it’s original packing and never used it will likely meet the same fate.

In fact that would probably be worse than using a deck everyday. If a

deck is used very regularly the rubber parts seem to have less

opportunity to glaze up. We stock hundreds of belts and tires, but even

then we only have about a 20% (that’s one out of

5) chance of having or

even having access to the correct replacement rubber parts.

Manufacturers of rubber parts are supporting cassette, reel to reel and

8-track cartridge technology less and less all the time due to lack of

popularity / demand. Internal tires that are still potentially serviceable, are

resurfaced / reconditioned. If they are too far gone, they

can also be sent out

to be rebuilt (people that do that are 'few and far

between'). We clean and re-lubricate the transport

mechanism. This commonly requires a complete disassembly of the

transport mechanisms moving parts. Cleaning a transport on a reel to

reel can sometimes be akin to cleaning the dried grease from under a 20

year old automobile. Very commonly the lubes / grease has hardened and

must be scraped off parts. Many times, bushings will be "frozen" on a

shaft and must be heated just to separate the two parts before cleaning

can even begin. No amount of lubing over a varnished joint will bring it

back. They must be disassembled, cleaned of all old lube and correctly

re-lubed. Auto-Stop mechanism wires are disassembled

and new 300,000 or 500,000 silicone damping gel applied. Capstan's are cleaned / burnished. Flywheel bearings likely re-lubed.

. Fortunately it takes longer than a year, but it does typically

appear after about 8-12 years. Even if a deck is left wrapped in

it’s original packing and never used it will likely meet the same fate.

In fact that would probably be worse than using a deck everyday. If a

deck is used very regularly the rubber parts seem to have less

opportunity to glaze up. We stock hundreds of belts and tires, but even

then we only have about a 20% (that’s one out of

5) chance of having or

even having access to the correct replacement rubber parts.

Manufacturers of rubber parts are supporting cassette, reel to reel and

8-track cartridge technology less and less all the time due to lack of

popularity / demand. Internal tires that are still potentially serviceable, are

resurfaced / reconditioned. If they are too far gone, they

can also be sent out

to be rebuilt (people that do that are 'few and far

between'). We clean and re-lubricate the transport

mechanism. This commonly requires a complete disassembly of the

transport mechanisms moving parts. Cleaning a transport on a reel to

reel can sometimes be akin to cleaning the dried grease from under a 20

year old automobile. Very commonly the lubes / grease has hardened and

must be scraped off parts. Many times, bushings will be "frozen" on a

shaft and must be heated just to separate the two parts before cleaning

can even begin. No amount of lubing over a varnished joint will bring it

back. They must be disassembled, cleaned of all old lube and correctly

re-lubed. Auto-Stop mechanism wires are disassembled

and new 300,000 or 500,000 silicone damping gel applied. Capstan's are cleaned / burnished. Flywheel bearings likely re-lubed.

One issue specific and common to many of Akai Reel to

Reel decks are disintegrated 'transport cams'

on Akai models such as, but not limited to,

Akai

1722W, 1722-II, X-150D, X-220D, X-1800SD,

4000, 4000DS, 4000DB, GX-4000 and many more.

on Akai models such as, but not limited to,

Akai

1722W, 1722-II, X-150D, X-220D, X-1800SD,

4000, 4000DS, 4000DB, GX-4000 and many more.

We inspect for any “cold” or loose solder joints especially on the input

/ output jacks and ground / ground-chassis, pots and switches or any

other parts that might have force or flexion applied to them. RCA jacks

are notorious for developing loose solder joints especially on gear

newer than 15 years or so due to manufactures choosing to solder jacks

en-mass directly to the circuit boards to save money. Cheaper as it may

be, it’s a terrible design that will inevitably fail after just a few

uses. The same goes for abandoning the use of quality control pots that

use a nut to secure it to the chassis / face-plate. Many units

manufacturers switched to using control potentiometers that are soldered

to the circuit boards and simply stuck through a hole in the face

with no “shaft nut” to secure it. Every time you manipulate the control

you stress the solder joint. Some fare well,

but most do not over just a few

years of use. Two terrible designs that are common on the vast majority

of gear manufactured after the early 1980’s but I just had to get on the

“Soap Box” about them. We also proactively

re-flow most solder joints associated with 'heat' producing components

such as 'voltage regulators' and 'power resistors' as even though they

may not 'yet' be completely bad, they are almost always in some 'state

of going bad soon'. We check the power

supply and make sure the voltages its producing is within spec. We then clean the heads and adjust head azimuth

w/ a 10kHz, factory azimuth tape and an oscilloscope for maximum

accuracy, phasing, output and sound quality. We check

with a 400Hz and 700Hz @ 0dB tape to check PB and Meter levels, and to

check for distortion (we're always listening / looking for that). Next we completely

demagnetize the heads, capstan and entire tape transport. Reel brakes

are adjusted on reel-to-reel decks. If the service is on an 8-track, we

will disassemble the track indicator and head track slide, to clean and

re-lube and burnish or re-spring the contacts for trouble free service.

We will also use factory 8-track service tapes to adjust for cross-talk

which is a common problem. 8-Tracks also commonly will have their

capstan flywheels remove to remove the old varnished lube, and re-lube.

Transport has any necessary adjustments made and lubricated where

applicable.

If the unit being serviced / refurbished / restored

is a Reel to Reel deck, reel hub force is measured and adjusted, as well

as tension arm springs, pinch roller force and motor 'back torque' using

appropriate scales (commonly in 'Dynes' or 'Newtons').

Most 'record capable' types of tape decks will need their internal

'record / play' slide switch extensively cleaned to eliminate many

issues.

.JPG)

.JPG)

Next we test record using a fresh, high quality tape looking

for large discrepancies in record / play-back meter levels. We also

re-test for speed accuracy and make any necessary adjustments that are

available. WE HAVE NEVER DONE THE INITIAL TESTS ON ANY TAPE DECK WHERE

WE HAD A DECK BE "ON SPEED", OR EVEN A USEABLE LEVEL OF "CLOSE". R2R's

are usually 20-120 cycles low at 1kHz, but can occasionally be sharp by

as much as 30 cycles (some late 60's-early 70's decks have actually been

150-300 cycles low!). Consistently, or at least 95+ % of the time,

cassette decks are 35-45 cycles over 1k after reaching operating

temperature. All the tape deck techs here (including myself) are

musicians and know what this means. This means that if you try and use a

cassette deck (or any tape deck for that matter) that has not been speed

checked, and it is 35-45 cycles "sharp" @ 1k, that is almost a entire

"half step" sharp (ie; if a song was recorded in the key of

"B", it will play back at a "C"). Try and match

with your old studio tapes to your voice or currently tuned instrument

at A440. Ain't gonna happen! We strive to adjust our decks to within +-

1cycle @ 1kHz and are usually successful. This requires a "factory" or

verified test tone tape, a calibrated frequency counter, lots of

patience and the knowledge of how to make the necessary internal

adjustments.

Next face plates / housings / patch-bays and knobs are painstakingly

cleaned and polished. Entire unit is detailed to look as close to new as

practical. Bent control shafts are straightened. Questionable or stiff

AC cords are replaced. Wood cabinets are oiled. Loose trim is repaired.

The unit is then re-tested for all functions.

Once the mechanical items and issues are addressed, the internal

controls are set to optimize meter levels, PB and Rec levels, and any

other levels that are practical. We then do many test recordings using

fresh, new (we have a stock of sealed, never used tape for our own use)

tape. Playback is tested with known quality and factory test tapes.

Cross-talk is checked with a factory 'cross-talk' test tape. If the deck

is a "record capable" unit, then recordings are made on both Normal and

Hi-Bias tapes for comparisons and are also made at multiple signal

levels and with the decks NR features on and off. We look for dB level

similarities upon playback and utilize an oscilloscope to monitor the

deviation of the original 1k signal and the recorded signal on each tape

type. We also then make multiple recordings from CD material that are

audiophile worthy (many CD's aren't). As with all our units, the entire

"pre-test" and "post-test" procedure is logged in detail in a report we

keep on file. Once the above is completed (and I've

probably left out a few steps) by our tech(s), it goes to me to have

final testing / auditioning. I will complete a 'post service' check

sheet. More often than not, a unit will require additional 'tweeking' /

re-visiting by the tech 2-5 times before I finally sign off on it (I've

been know to 'terminally fail' units even after 4-5 tech visits if it

doesn't perform to my standard, and to a level that I think justifies

our values and will give good service for MANY years or decades to

come). The above steps and procedures can take from 10-40 hours to

complete (typically 16-24).

(PS. If you're looking at auctions for 20+ year old units, and someone

says, "this tape deck (substitute VCR, Turntable, CD player, Clock or

other electro-mechanical device) has never been used or taken out of the

box" or, "was used for a couple of hours when new, and has been in the

closet ever since" those are BAD THINGS! Probably one of the worst

things that can happen to an electro-mechanical unit such as a tape

deck, turntable, VCR, etc. is for it not to get used. Just like a car

that runs bad after it sits for a few weeks or months, a stereo

component can have similar symptoms. Think of how bad the car would run

if it hadn't been started in 15 or 20 years! On tape decks, Turntables,

VCR's etc. that have been allowed to sit unused, the rubber parts /

belts stiffen into one shape and the lubes congeal or worse yet turn to

varnish, "freezing" moving parts solid! So the next time you hear, "its

new in the box and was never used" when referring to an

electro-mechanical device, think twice and "run like h3ll".)

Photo is of a Teac 4010S having typical Main Capstan Belt change and Pinch

Roller Arm re-lube operation. Not an operation too many folks want to

undertake. This is just a couple steps of MANY that is required to try

to get most decks back to a level of condition that will allow it to

operate for any length of time! Just FYI.

Photo is of a Teac 4010S having typical Main Capstan Belt change and Pinch

Roller Arm re-lube operation. Not an operation too many folks want to

undertake. This is just a couple steps of MANY that is required to try

to get most decks back to a level of condition that will allow it to

operate for any length of time! Just FYI.

Speakers:

Each speaker first gets a visual inspection for

bad surrounds, dust cap condition, cabinet joint integrity, connector

condition etc. After some pre-testing of the individual drivers, any

speaker that comes in with drivers (especially woofers) featuring foam

surrounds has the foam replaced on those drivers, except in very rare

cases. We do this regardless of how "good" the foam may still "look" on

a driver. We learned this the hard way as that long ago when we first

started in the "vintage" biz, we would "pass" speaker with drivers that

had foam that "looked" fine. 100% of those 6 or 7 times we sold speakers

that way, the customer called within a day or two of using them to let

us know the foam had failed, so they had to be shipped back for

re-foaming anyway. (By the way, the truly 'correct' method of

re-foaming / replacing speaker surrounds, especially on drivers larger

than about 6", and on certain drivers smaller than that, is to 'shim the

voice coil'. This requires removing the dust cap. Yes, its difficult

and potentially damaging, but you just need to be careful and

methodical. If that is not done, there are two alternative methods to

'centering' to voice coil. The first is 'by feel'. VERY inaccurate and

generally only successful by SHEER LUCK. Kind of like setting the timing

on your engine 'by ear'. Yes, you MIGHT get close, and the end result

MIGHT be a better running engine, but it probably won't be nearly as

correct as using the correct equipment. The other method of centering

the voice coil involves sending a VERY low frequency tone (DC or

approaching DC) to the voice coil to keep it centered in the gap and

keeping it there while the glue sets up / dries. Firstly, few folks have

the ability or equipment necessary to do this, and secondly, I wouldn't

want DC, even at lower power levels, to be sent to my voice coils for

extended periods of time to 'cook them'. (an alternative method to the

'DC' version is to raise the frequency to as much as 400, but then you

have a 'vibrating' cone that makes 'weighting' the foam all the way down

on the cone nearly impossible, which will likely result in a glue joint

with 'gaps' and unnecessary glue mass). I am amazed at the lack of

credence given to this issue with firstly the folks selling re-foam

kits, and secondly the general public installing them. A few years ago,

most kits and instructions would include the necessary shims,

replacement dust caps, and information on how to remove your dust caps,

shim the voice coils and replace the dust caps. Now I am not aware of

any that do! Maybe it was causing too many 'customer service' issues /

'call backs' and maybe folks were ruining their drivers removing the

dust caps. I can only speculate but its a shame, as its a disservice

and a misfortune that probably many drivers are likely 'ruined' by

incorrect re-foam jobs. There's not a 'pretty' fix I suppose, but if

doing the job correctly is beyond someone's capability, then the drivers

should be sent to a 'competent' repair shop (competent meaning a shop

that correctly 'shims the voice coils') and have them done there)

The units are then disassembled where practical to inspect for physical

condition of drivers, crossovers and type / quantity

dampening material. You would be

surprised at what we’ve found in some speaker cabinets. Everything from

rusty speaker frames and motors, exploded caps in the cross-over that

have sprayed “shrapnel” throughout the inside of the cabinet, charred /

burned crossover networks (speaker may still work, with a crossover that

looks like its been barbequed), mouse nests and once, even a Black

Widows web with resident about the size of a quarter still alive and

well. Not sure what she had been eating in there.

We next check for driver spider (not the same as the above mentioned,

but an actual part of a speaker) attachment and lead wire integrity. We

also check for loose internal wiring / connections. Drivers are then

re-installed adding or replacing gasket material with fresh. We also add

fresh gasketing material to the rear panels / baffle boards where

applicable. Once the drivers are re-installed the entire speaker system

/ cabinet is 'vibration' tested with 'drop tests', mallets and an

amplified AF sweep (this is where we almost always find issues, many of

where were probably there from the original manufacturer!). Next each

speaker is individually tested. We use a pink noise generator as testing

with music material from a CD or other similar source will many times

not alert you to Tweeter, Super Tweeter open coil issues or other

"balance" problems. The PN generator

will also alert us to any 'phase' issues, not only between the L & R

drivers, but within a cabinet, between woofer and midrange. This is one

place that I commonly have to 'triple and quadruple check' my

technicians on, as its any easy one to overlook on 're-assembly' after

they've spent hours working on a speaker. The PN generator is also how we find most issues

with driver attenuators both prior to and after cleaning (and pretty much

all have contact issues prior to our refurb).

Many speakers may sound OK

with recorded material, but can have their upper-most-frequency

drivers

bad. We then test the entire speaker cabinet with it’s components

in-place with a sweep tone generator at low, medium and high volumes to

check for any buzzing, rattling, extraneous vibrations,

air leaks / 'whistles' (commonly found from 80Hz down to 20Hz or so) or sympathetic

harmonic tones. We

recently had a pair of Pioneer HPM-100's that we came in with three

'hidden / not-apparent' issues. One was a 'blown apart' capacitor on the

crossover (all the drivers still functioned, and that would not have

been discovered, had we disassembled the speaker), and the second issue

was one of the tweeters had a 'buzz' we found during a 'sweep' from

approx 2.3kHz down to about 900Hz. We substituted another (after

ordering from an on-line auction seller (you guess which 'on-line'

auction) and waiting for it to arrive), and it also had a similar

'buzz'. We were then forced to take one from a Pioneer HPM-100 in our

personal collection, and yes, it worked fine. The EXACT same scenario

happened with one of the 'Super Tweeters', except that it worked

'intermittently' when removed and had the case 'flexed'. That cost's us

over $200 just in tweeters, and while most folks may never have noticed

the issue, IT WASN'T RIGHT, and had to be addressed. We also replaced

the crossover (actually was quicker and easier to replace in its

entirety, then to just replace the blown cap).

We then test both speakers as complete assemblies with

pink / white noise to check for driver balance between the two cabinets.

This is not only an audible test, but we are able to view the results

with our 1/3 octave, 31 band RTA with calibrated mic that registers

20-20kHz. Next a number of recorded selections / cuts for sound quality

(another fun part of the job).

Entire unit is then detailed to look as close to new as practical. New,

felt feet are usually installed and any grill issues are rectified as

practical. Where applicable we oil wood cabinets, lightly repair

veneer, then bag and tag them to await packing (which is very difficult

to do correctly) for safe transit for shipment.

Recent and past speaker technicians include Camerion Gholson, Mark

Vandergift, Shane Thurston and John

Wright.

(BATCH OF SPEAKERS AWAITING RESTORATION)

Turntables:

We first do a visual check of the table and

cartridge / stylus if applicable. If it’s a belt drive table we see if

the belt is still intact, missing or on occasion a natural rubber belt

will have disintegrated and wrapped itself around the motor capstan thus

burning up the motor as it could no longer spin due to the excess rubber

around it (we recently had a Philips turntable with this condition.

Fortunately the motor was still fine once the rubber ‘goo’ was cleaned /

removed and motor was re-lubed).

We check the tone-arm Gimbal bearing for freedom of movement and the arm

lift mechanism for smooth operation.

We check the ‘oil / fluid damped’ cuing for correct lift / set-down

speed, and if necessary, disassemble, clean and re-invigorate with

100,000, 300,000 or 500,000 silicone damping gel (post tests determine

if the gel weight is correct).

We then remove the platter to measure for a new belt and to lubricate

the motor, to check / replace any thrust bearings, and clean and

re-lubricate the spindle bearing.

We inspect, clean and re-lube any ‘auto-arm’ mechanics. This is usually

the most time consuming and ‘risky’ part of any turntable restoration.

Most are ‘fairly complicated’ internal workings, with many moving parts

that react with other parts, dependent on MANY points to be clean and we

lubricated. We recently had one require 20+ hours to rehabilitate! More

typically they require 4-8 hours to address ‘auto-arm’ mechanics,

especially on ‘mid-1970’s’ tables and earlier.

Pioneer PL-50 in restoration

process.

Once the mechanics are complete, we move on to the electronics / sonic

aspects.

We check the patch cables if permanently attached for condition, correct

resistance and replace / ‘up-grade’ where necessary.

If the patch cables / interconnect cables are ‘detachable’, we check the

integrity of the RCA jacks and re-flow solder joints as necessary.

We then make any necessary repairs to the base and when practical to the

dust cover and check it’s ‘hinge’ condition for joint issues and ability

to ‘hold’ dust cover up-right, adjusting if necessary, and when

possible.

We then install a “demo / test” cartridge / head-shell to put the table

and all it’s mechanisms through their paces and make any necessary

adjustments / parts replacements.

We then check for speed deviations, and correct where necessary /

practical / possible. While we strive to get an end result of 99%, +/-

1%, some tables will not allow closer than 95% speed accuracy.

Once we are satisfied the mechanics of the table are operating

correctly, we then test for proper and adequate ’60Hz Ground’ correcting

where necessary and improving it internally when possible.

We check, test and adjust any internal ‘muting’ micro / reed switches.

We then remove the “tester cartridge”, replacing it with the 'intended'

cartridge and optimizing the tone-arm for it checking ‘overhang’ and

adjusting through gram weight range, and making sure that ‘anti-skate’

calibration is similar to what it’s indicators state.

Then we use various test LP’s through speakers and a Dual-Trace

oscilloscope (on the mid-upper end price range tables we sell) to adjust

for anti-skating and cartridge cross-talk, tracking capability,

distortion from one channel to the next, and check for the cartridges

ability to track test records correctly on signals that are recorded

progressively louder. This is sometimes referred to as a ‘cartridge

obstacle course’. We may utilize a ‘blank slate’ record to adjust

anti-skating / bias (we’ve found it’s the most accurate way, even over

our O’scope / test record method). We also generally make notes as we go

through turntables recording what the end results of many of the

operations / tests were.

We then clean and polish the cabinet and dust cover as much as is

practical. When ‘monetarily practical’, dust covers are brought to near

new condition. Our guy is amazing with them.

Any dustcover

cracks (usually near the hinges)

are ‘welded’ for structural integrity. Entire unit is detailed to look

as close to new as possible / ‘monetarily practical’.

Any base / case issues are addressed prior to

re-assembly.

The tables are then bagged and tagged to await

packing (which is no easy task on a turntable) for shipment.

Turntables are one of the most difficult items to pack for safe shipment

and streamlined ‘re-set-up’ once the table arrives. That is for another

discussion / page.

Here's an example of what our turntable tech can do for the cosmetics

alone:

(click on thumbnails to view photos)

(click on thumbnails to view photos)

(PS. If you're looking at auctions for 20+ year old units, and someone

says, "this tape deck (substitute VCR, Turntable or other

electro-mechanical device) has never been used or taken out of the box"

or, "was used for a couple of hours when new, and has been in the closet

ever since" those are BAD THINGS! Probably one of the worst things that

can happen to an electro-mechanical unit such as a tape deck, turntable,

VCR, etc. is for it not to get used. Just like a car that runs bad after

it sits for a few weeks or months, a stereo component can have similar

symptoms. Think of how bad the car would run if it hadn't been started

in 15 or 20 years! On tape decks, Turntables, VCR's etc. that have been

allowed to sit unused, the rubber parts / belts stiffen into one shape

and the lubes congeal or worse yet turn to varnish, "freezing" moving

parts solid! So the next time you hear, "its new in the box and was

never used" when referring to a mechanical device, think twice.)

Effects, Tuners, EQ’s and other

signal processors receive much of the same attention as the afore

mentioned units.

Vintage

radios:

We first do a visual inspection of the chassis

and cabinet. We then remove the chassis from the cabinet and do a visual

on the circuitry. We note weather the tubes that are in the sockets are

the correct units. Many people will stick a tube into a socket because

it fits and looked the same or it’s what they had around. That usually

spells smoke and disaster for the radio and certainly the tube and on

occasion the operator. We look and see if any of the filter capacitors

are swollen or leaky. We also inspect the AC cord to see if it’s safe

enough to at least test the unit with. If everything looks in order we

then apply AC power slowly to the chassis with a vari-ac noting

current draw. Sometimes by the time we get up to only 20 or 30 volts a

radio will start drawing ½ - 2 amps and we know we have a problem.

Sometimes they will power up fine, but just buzz loudly. Sometimes they

start working with only the normal 60 cycle hum from an aged power

supply filter circuit. Once we deduce the initial electronic condition

of the chassis we then cut the power to the radio. We next remove all

the tubes, noting their correct location, test them, record the findings

on the tube with a sharpie or replace them where necessary (we also test

the new ones as we have had plenty that were bad out of the box). We

then clean the chassis completely including all the tube sockets. We

next check and almost always replace all the electrolytic filter

capacitors as well as checking all the other caps. We then clean all the

controls, switches, contacts and the variable tuning capacitor as well

as lubricating any moving parts. We then check the dial cord and

mechanism for integrity. We replace the pilot lamp and any other light

bulbs. We next install a new polarized AC cord and add a fuse for

safety. We then install all the tested / replaced tubes and again slowly

power the radio up through the vari-ac. After a couple of minutes

warming up at this point they usually sound like new! We then

disassemble the cabinet thoroughly cleaning the dial glass and

cleaning and polishing the housing and knobs where applicable. Entire

unit is detailed to look as close to new as practical. We then

re-assemble the entire radio and test play for at least 2 hours. They

are then bagged and tagged to await packaging for shipment.

Vintage electric fans:

Fans are very labor intensive

for us. That is why we are slow to replace sold units. Each fan

is initially tested, if they appear safe, for function, spin balance,

oscillation (if applicable), speed switch function and excessive rattles

or noise. We are also looking for speed and the amount of time the fan

may take to come up to speed. We then completely disassemble the fan and

all it’s components. We remove and clean any dried lubricant from the

oscillation mechanism (where applicable) and re-lubricate it. We also

try and replace any missing / broken parts to the oscillator. We then

clean and check the motor and it’s windings. We also check the brushes

at this point. We then check the condition of the speed / on-off switch

and repair as necessary. We next check the condition of the cage (blade

guard) inspecting for broken welds and straightening any bent sections.

We then either clean and polish the existing finish or often will sand

the unit down and refinish it. We will also at this time polish the

blades if they are not painted models. Entire unit is detailed to look

as close to new as practical. Once the finish work is complete we will

then reassemble the fan installing a new AC cord at that time. The blade

is then balanced for the most vibration-free operation possible. We will

then run the fan for at least an hour to make sure it is ready to go. We

then bag and tag it to await packing for shipment.

Guitars:

We have been doing

guitar set ups and repairs for almost 20 years for the general public.

Everyone has their idea of what “Plays great” means, but our set-up will

please 90% of Professional players. We know how to assess fret wear,

tuner condition, neck relief and electronics. We also are familiar with

the different aspects of tone and sound that make, model, strings,

pickups, wood and etc can have. We check for fret wear, adjust neck /

body angle if necessary, adjust neck relief to correct amount, adjust

pick-up height, saddle height, check nut grooves for

correctness, disassemble-clean-re-lube tuning

machines when applicable

, install new strings, adjust intonation for installed

strings, check for excess buzzes and test play the instrument. We

also clean and polish the instrument, oil the fingerboard, polish the

frets, lube the tuners (if applicable) and make any necessary electronic

repairs. If a buyer prefers we can do a custom set-up for their playing

style and choice of strings.

, install new strings, adjust intonation for installed

strings, check for excess buzzes and test play the instrument. We

also clean and polish the instrument, oil the fingerboard, polish the

frets, lube the tuners (if applicable) and make any necessary electronic

repairs. If a buyer prefers we can do a custom set-up for their playing

style and choice of strings.

Keyboards:

Each keyboard is

initially inspected for performance. We then disassemble the unit

inspecting for battery leakage (common), condition (most keyboards

utilize a lithium battery for the memory which generally have a lifespan

of 3-7 years, and since most vintage keyboards are pre 1990 they almost

all need the batteries changed to function), corrosion, bad contacts

etc. We will thoroughly clean it inside and out. We then adjust /

replace / repair the key contacts, level the keys (if applicable

and when practical), check tune, replace any bad tines / reeds, repair

broken keys, do necessary case cabinet repairs, check electronics for

excess noise, re-solder bad jack connections, check foot control

functions, clean pots and controls, tune correctly and test play. Entire

unit is detailed to look as close to new as practical. Any keyboard that

cannot pass the above criteria after necessary, practical restoration

gets salvaged for parts.

Microphones:

We test each mic by ultimately going directly to

the element. As there are many different mic connector configurations

that both came stock and may have been modified by users, we

cannot guarantee that the mic will “out of the box” connect correctly to

your input. Most can easily be modified either by the end user or if

requested by us (a nominal fee will apply). Each mic is cleaned and

polished and it’s sound quality / operation condition noted.

Test Gear:

Test equipment is a varied department so the

tests / repairs we do to one is probably not applicable to another. Each

is cleaned inside and out to a practical amount. Each is tested

for function, calibration and accuracy. Tube testers have their internal

tubes checked, electrolytic caps checked / replaced, tube sockets

cleaned, controls cleaned and knobs tightened. O-scopes are checked

for basic function. Power supplies are checked for correct output and

regulation where applicable.

Electric Clocks:

Each clock is disassembled and thoroughly cleaned inside and out.

Mechanism is lubricated and checked for loose or non-working parts.

Motors are checked for freedom of movement and condition of windings,

brushes and bearings. AC cords are replaced and a fuse is sometimes

added where space will permit. Faces and hands are cleaned as well as

the inside of the dial crystal (glass). Finish touch-up are sometimes

made. Entire unit is detailed to look as close to new as practical.

Clocks are then re-assembled and checked over a 48 hour period for

accuracy. They are then bagged to await packing for shipment.

Due to limited resources we are only able to do restorations / repairs

on OUR OWN inventory

and unable to take OUTSIDE / CUSTOMER repairs.

If you need

work done to your gear,

TRY

SOME OF

THESE RESOURCES

WARNING:

PLEASE USE CAUTION WITH ANY ELECTRICAL DEVICE.

ANY REPAIR AND / OR

RESTORATION

SHOULD BE UNDERTAKEN ONLY BY A QUALIFIED TECHNICIAN. THE

TEXT'S BELOW

ARE NOT INSTRUCTIONS FOR DOING YOUR OWN REPAIR AND

ARE NOT

COMPREHENSIVE IN SCOPE.

*Amplifiers are

measured with .775 v, 1kHz Sine wave with amp at clip into a dummy load.

Amplifiers are each measured independently of each other.